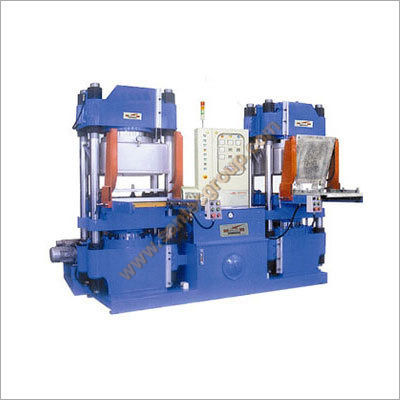

Compression Molding Press-325 Tons Capacity

Product Details:

- Color White, Blue

- Product Type Compression Molding Press-

- Usage Industrial

- Material Stainless Steel

- Warranty 1 Years

- Click to view more

Compression Molding Press-325 Tons Capacity Price And Quantity

- 550000 INR/Unit

- 1 Unit

Compression Molding Press-325 Tons Capacity Product Specifications

- Industrial

- White, Blue

- 1 Years

- Compression Molding Press-

- Stainless Steel

Compression Molding Press-325 Tons Capacity Trade Information

- Cash Advance (CA) Cheque Cash in Advance (CID)

- 1 Unit Per Month

- 2 Months

- Middle East Australia Eastern Europe Central America Africa South America Western Europe Asia North America

- All India

Product Description

Compression Moulding Press Machine

Backed by the rich industry base and experienced personnel, our company has been able to emerge as one of the eminent manufacturers, importers and exporters of Compression Molding Press Machine. Our offered range of molding machines is renowned for its rugged design and long working life. These molding machines are used in rubber industries, research & development laboratories for composites molding purposes. Compression Molding Press Machine is available in various specifications and models at competitive prices.

Application

- Engineering or Technical colleges to give training to the students . i.e. I.I.T. , NIT , Engineering Colleges etc.

- Research & Development Laboratories i.e. Sri Ram Institute of Industrial Research , SPIC Science Foundation, Vikram Sarabhai Space Centre, Indira Gandhi Centre of Atomic Research

- Big Rubber Industries for R &D applications i.e. MRF, JK Tyres etc.

- Composites Molding applications, Plastic Processors etc.

- Laminates and Plastic cards manufacturing

Salient Features

- A specially designed heating system ensures a high uniformity of temperature of the plates. For this reason, the press is ideal for moulding rubber & plastic sheets or samples for laboratory tests.

- Digital PID controllers - FUJI (Japan) / WEST Make provided for accurate temp. measurements.

- Lab type compression molding presses can also be successfully used for moulding small series of rubber or plastic parts for mass production too. The structure is very rigid & can work in 3 shifts.

- Covered from all three side except front side for loading & unloading of mould inside the press. Safety photo guard are placed on the front side for operator's safety.

- 4-pillar type construction hence better alignment.

- PLC with colored touch type display unit for user friendly operation.

- Automatic press control device for programming an automatic production cycle by inserting upto 5 degassing cycles & curing time for moulding. At the end of the programmed time, the press automatically opens and a beeper signals the end of the cycle.

- Precision alignment and parallelism of the platens

- Flexible controls for sophisticated compression profiling

- Front side Table with Ball Transfer units

- Light / Lamp for the operator

Standard Accessories

- Electric Motor & Pump

- Photo Safety Guard (Sick Germany)

- Front Light for Operator's Convenience

- PLC with coloured touch type Display screen

- Pressure Setting through PLC with the help of Pressure Transmitter

- Emergency Push Button

- Two Hand Push Button Operation

- Tower Light

- PID type Temperature Controllers Fuji / West make

- Mould Bank records in PLC

- LVDT (Potentiometer) controlled ram Movement

Optional

- Mold/ Platen Shuttles / sliding out arrangement

- Front side Tilting arrangement of the Top platen of the Press

- Thyristor to control the Multi temperatures during the curing time .

- Molded Part knockout arrangement

- Variable Displacement Pump.

- Data-Logger

- Mold plate ejectors

- Heating platens fitted with water recirculation circuit for the moulding of thermoplastic materials .

- Added safety enclosures

- Exhausts, enclosures for gas emissions

- Platen temperatures to 400 degree Celsius

- Mold thermocouple connections and temperature monitoring

- Multiple daylight designs

- Consolidated controls for multiple press systems

- Vacuum pump and reservoir

- Steam or oil platens

- Transfer molding cylinders and controls

- Core Pullers for middle part of the mold

|

Description |

LCMP-10 |

LCMP-20 |

LCMP-30 |

LCMP-50 |

|

Capacity (Tons) |

10 |

20 |

30 |

50 |

|

Platen Size (mm) |

200x200 |

300x300 |

300x300 |

400x400 |

|

Construction |

4-Pillars |

4-Pillars |

4-Pillars |

4-Pillars |

|

Ram Movement |

Up Stroke |

Up Stroke |

Up Stroke |

Up Stroke |

|

Daylight (mm) |

300 |

300 |

300 |

350 |

|

Stroke (mm) |

300 |

300 |

300 |

350 |

|

Temperature (Degree Celcius) |

400 |

400 |

400 |

400 |

|

Electrical Motor (H.P.) |

3 |

5 |

5 |

5 |

|

Pressure Adjustment |

Pr. Trans Mitter |

Pr. Trans Mitter |

Pr. Trans Mitter |

Pr. Trans Mitter |

|

Heating Method |

Electric/Oil |

Electric/Oil |

Electric/Oil |

Electric/Oil |

|

Power Supply (Volts) |

415/380 |

415/380 |

415/380 |

415/380 |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese